In the field of nylon compounding, have you encountered these challenges with your twin-screw extruder?

1, Poor mixing or dispersion leading to unstable product quality?

2, Excessive shear and material yellowing?

3, Low throughput under high filler loading?

The root of these issues does not depend solely on the process but is also closely related to the equipment’s core components — namely, the screw elements, shafts, and barrels of your twin-screw extruder.

Lesun’s main products: screw elements, shafts, and barrels.

More Uniform Mixing

Nylon modification demands extremely high requirements for dispersion and distributive mixing. Lesun’s specially engineered screw elements optimize distributive and dispersive mixing, minimize shear degradation, and improve the mechanical properties and appearance consistency of the final product.

More Stable Processing

The precision and consistency of screw elements, barrels, and shafts directly affect melt conveying and product quality. Even tiny deviations can impact the performance of modified nylon. Lesun ensures the stability and reliability of every batch of material through high-standard precision manufacturing.

Reliability Under Higher Torque

Nylon modification is evolving toward higher filling levels, stronger alloying, and greater efficiency. High-torque twin-screw extruders play a key role in boosting conveying capacity, production output, and energy efficiency — all of which rely on the exceptional mechanical strength and reliability of core components.

Lesun is investing over 30 million RMB to introduce advanced international cold forming technology, with full-scale production scheduled for 2025. This process significantly enhances shaft surface hardness, fatigue strength, and dimensional stability — solving long-standing stability and reliability issues in ultra-high torque extruders (torque factor >13).

Suitable for: high-temperature nylon, long-chain nylon, high-glass-fiber reinforced PA, and other high-performance engineering plastics.

This marks a breakthrough in both equipment stability and material processing performance.

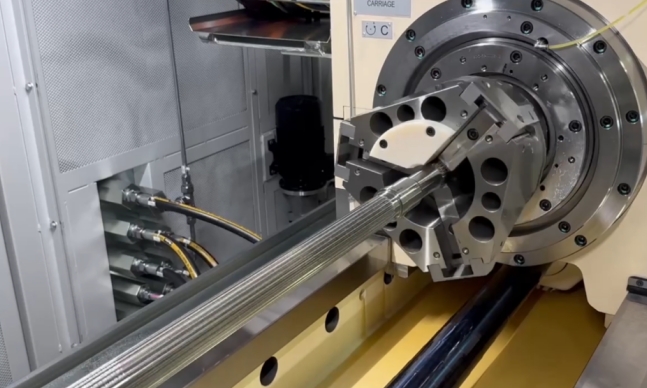

Cold-forming processing of screw shafts

In the demanding production of nylon modification, true stability and reliability lie in the technical expertise behind every precision component. Lesun Screw helps you confidently tackle every processing challenge in nylon modification.