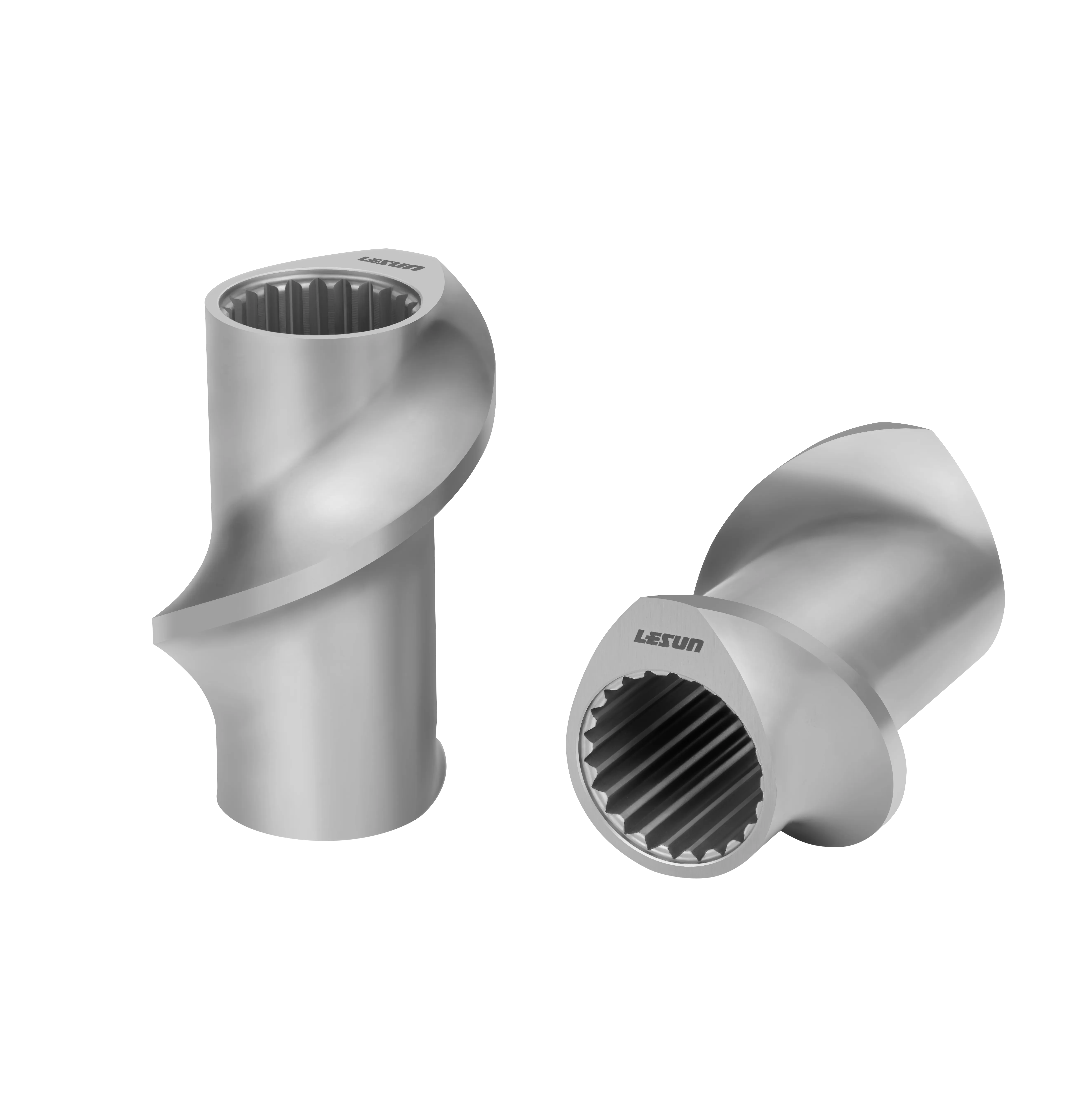

The single-flighted conveying elements have better conveying capacity than the standard two-flighted conveying element, but it reduces the free volume of the screw, and the single-flighted conveying elements have a wide screw edge, which is conducive to reducing leakage flow, and is mostly used in the feeding and extrusion zone.

Model:Φ18mm~φ400mm

Material:N00/W6/HIP

Properties: Wear-resisting, Corrode-resisting and Durable

1.Excellent performance on conveying function

2.Short and defined residence time

3.Good self-wiping characteristics

4.Pressure build-up